This is going to be a bit of a long post, but I tried to remember more or less the sequence of events and everything we did, in case that helps anybody out!

Oral

As usual, we started with the oral. Pretty straightforward. It was both of us in there at the same time, which was a first for me. The examiner would just alternate asking questions between the two of us. Started with some of the memory items from the checklists (Engine fire before V1, go!) and then went through some of the limitations (flaps extended speed, autopilot limitations, thrust reversers, etc.). Both of these areas were straight off the flashcards or study guide provided in the training materials. So, no real surprises if you studied.

He then went to a large poster of the cockpit on the wall and proceeded to ask us questions about various buttons and switches and the systems they controlled. "What happens when we turn the engine anti-ice system on?" "How long should the surface deice light be on for once activated?" "If the AC Fail light comes on, what systems do you have left?" These also were pretty straightforward, taken from the training materials and ground school lessons. Fortunately, there were no questions like "draw a schematic of the electrical system" or "how many holes are in the speedbrakes?"

Then it was time for the "preflight". Since we didn't exactly have an actual airplane in the building, it was a bit funny how they did this. There is a video we had watched in class about the preflight, so he just played it and muted the sound. He'd ask "what is the pilot checking now? What is he looking for?" - those kind of questions. Since I had (literally) used the video to help me fall asleep a couple times at night (yes, really), this was also no problem.

You see, the Citation II is not a new airplane, and this video was made quite a while ago. And it shows. Enjoy.

https://www.youtube.com/watch?v=ssGftj4xX8I

Now it was time to figure out our Takeoff and Landing Data for our TOLD cards. It's just a matter of looking up the proper numbers for weight, temperature and altitude.

Having passed the oral, it was on to the flight!

Flight

I'm pretty sure I have the sequence of events right here, but it's very possible I've missed something. It was a busy day!

- Complete cockpit checklist as if we just walked out to the airplane.

- Right engine start

- Rapidly rising Interstage Turbine Temperature (ITT) indicated a hot start, so I shut the engine back down.

- Normal start on both engines

- Short taxi for takeoff

- Takeoff roll

- ENGINE FIRE light on before V1, abort takeoff

- Normal takeoff

- Kennedy Five Departure out to the "practice area" near the DPK VOR

- Steep turns (360 degrees, 45 degrees of bank, left then immediately followed by right)

- Stalls in clean (autopilot on), takeoff (autopilot off) and landing (autopilot off) configurations

- Unusual attitudes

Done with airwork, now back for approaches.

- Direct JFK VOR for the VOR RWY 4L, circle to 31R (autopilot available)

Now, I've done a few circling approaches, especially in training, and of course the visibility is usually pretty good when you're actually out there flying for training. The examiner took the visibility down to something just above minimums, maybe 1 1/2 miles? 2 miles? With the cloud deck right above me, it was definitely a different experience. The runways were hard to see in the first place, let alone maneuvering to line up with a different one. I'm sure that's why many operators prohibit circling approaches altogether. I really wouldn't like to have to do one in those conditions for real.

- Takeoff

- Engine problem after V1 (we noticed a runaway ITT)

- We continued the takeoff and climbed to 2000 and shut it down in the air.

- Based on the ITT problem, we elected to not attempt a restart. So now it was single-engine operations for a while.

- Vectors for the ILS RWY 22L (autopilot available)

- At DA, no runway in sight, missed approach (single engine still, of course)

- Vectors for the ILS RWY 4L (autopilot not available, hand flown)

This is the approach that had caused me problems the day before - I was weaving back and forth on the localizer and I suspected it was due to rudder trim not being set right. So before I started this approach I made sure I had it set right! And ... ta-da!

That's way better than the day before! Amazing what a simple few turns of the rudder trim wheel will do. Runway in sight just before DA, and landed.

- Takeoff, climb to 2000, engine failure as we level off (man these engines have problems!)

- Engine shutdown then successful restart

- Vectors to the IF for the RNAV (GPS) RWY 4L (hand flown, only LNAV minimums available)

- A little bit of twiddling with the FMS for this one

- The weather had improved a little, so we got the runway in sight, descended to land, but a go-around was called by tower at about 50 ft.

- Vectors for the visual approach to runway 22R

- Flaps would not extend, so we got delay vectors to run the appropriate checklist

- Landed!

And then I heard the words I wanted to hear - you passed! About a 2 hour flight.

Sim partner's turn

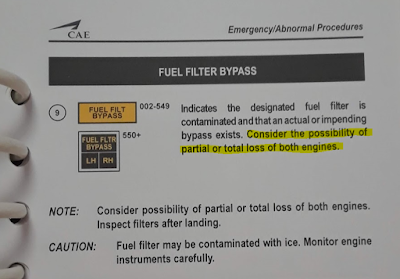

Now it was my sim partner's turn to fly, which meant I was now the copilot. We had learned that the copilot is often much busier than the pilot when it comes to emergencies. Finding and running the checklists can keep you pretty active.

In some ways, I was more nervous about being the copilot than being the pilot. For one, there are so many ways where mistakes made by the copilot could really cause problems for the pilot that would lead to a checkride failure. Setting the wrong altitude, wrong frequency, bringing up the wrong checklist, missing an item on the checklist, etc. I didn't know how the examiner would handle a situation like this, and I sure didn't want to find out! My sim partner had done a decent job for me, I wanted to do a decent job for him.

His checkride was basically the same as mine. Some of the engine failures were for different reasons, but I think the general flow was the same. And apparently I did a good enough job as copilot, since he passed too.

For a last little bit of humor, the examiner had us taxi up to the gate at JFK to end the day. Not really built for a Citation!

Ahh, the moment I've been waiting for...

Temporary certificate in hand!

|

| DPE: Vinay Singh |

Since this is my first type rating (and I don't have a bunch of previous turbine time), my certificate is going to be a little wordy for a while. I require what is called "SOE" - Supplemental Operating Experience. The FAA words that as "The CE-500 is subject to Pilot-in-Command limitations." This means that for the next 25 hours, I must be flying with another fully-type-rated pilot. This should not be much of a limitation for the type of flying I'm looking at doing.

Also, since the Citation II is eligible to be flown single-pilot (if the pilot has passed the additional checkride for those privileges, which I of course have not), my certificate also reads "CE-500 Second in Command required." Which for those 25 hours will be another PIC-rated pilot. Once I meet the SOE requirement and get the limitation removed, I could fly with someone who is only Second-in-Command qualified.

|

| In red - my new rating. Highlighted - the additional limitations! |

If anybody has any questions about the process, or the school, or what it was like going from Bonanzas, Comanches and light twins to a type rating, just let me know, I'll be happy to answer any questions.

I am really looking forward to flying the Citation II!

|

| (photo from Wikipedia) |